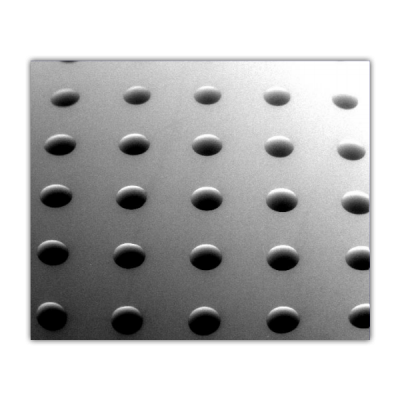

Precisely and accurately placing adhesive lines and dots on diverse substrates and electronic devices is a core process for the 3Dn Series, SVA Series, and SmartPump™ tool head. The 3Dn Series and SVA Series provide exceptional motion control with feedback to insure a quality print on every device, every time. With speeds up to 10 dots/ second and lines up to 500 mm/second, our systems provide high throughput with exceptional quality for any adhesive application.

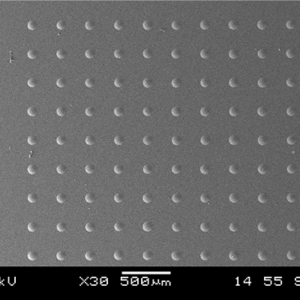

The SVA Series is preconfigured and optimized for precision microdispensing of adhesives and other materials, at speeds of 1500 or 3000 dots/hour. The SVA 3000 is a SMEMA standard tool for in-line production. This series is top of line for industrial manufacturing, consistently printing adhesive dots down to 75 microns.

With exceptional volume control (up to 100 picoliters), the SmartPump™ provides excellent starts and stops (with no drooling) for lines and repeatable shapes for dots. The SmartPumpTM microdispenses a wide range of loaded and unloaded adhesives with low, medium, and high viscosity. Once the SmartPump™ has been optimized for a specific adhesive, no additional tuning is necessary. The results are highly repeatable through millions of pumping cycles.